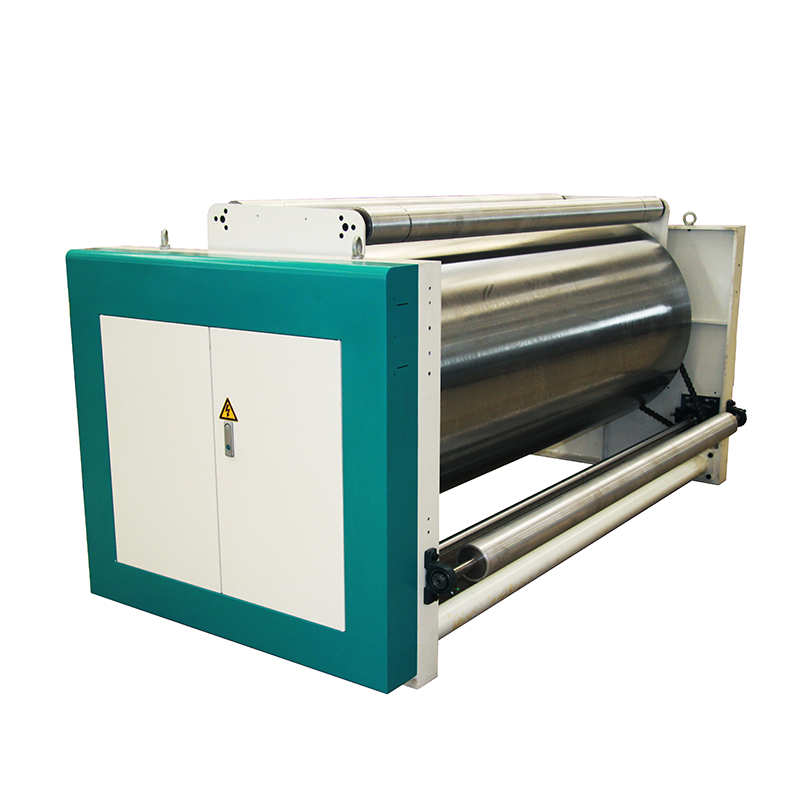

Single Facer

To get more details about Single Facer Laminating Machine, pls visit here

Cassette Single Facer

* Electrical trolley(Equipped with famous brand driving motor)

* Tungsten carbide corrugated rolls(φ408/φ360),type of flute according to customer needs

* The modular design has been applied in the corrugators which can be beneficial for the maintenance and repair

* Because there is no gear box in the machine, so the shake and noise will be reduced. Non-gear box also easy for maintain, more energy saving, more energy saving

* Less than 15 minutes to switch the corrugated roller.

* Hydraulic control system to ensure stable operation of the machine

* High precision glue clearance adjustment, automatic mode with the speed of the automatic adjustment, reduce the amount of glue loss

* The automatic idle rollers function, when the temporary shutdown, avoid glue dry on the roller surface

* Gluing unit could be move out, make the clean and maintain easier.

* Water circulation cooling device to ensure the stability of glue

* Tungsten carbide corrugated rolls make sure its service life more than 30 million meters.

* The gaps between upper corrugated roller and gluing roller, gluing roller and glue cleaning roller using electric trimming and numerical display

* The medium spray device can adjust the temperature and humidity of the medium paper

* Paper break detection system for the medium and liner paper

Single Facer

Single Facer

Shaft Less Hydraulic Reel Stand

* Maximum diameter of mill roll: 1500mm

* Maximum weight of mill roll: 4500kg

* Durable design and full hydraulic drive which can guarantee the machine is working reliably and stably

* Applying expansion collet to avoid damaging the center of mill roll (3" - 4")

* Pneumatic multiple point brake make the paper tension be stable, Following with unloading device which is more convenient and fast

* Central integrated control platform which can control the splicer and hydraulic rail

* The splicing speed, radius of mill roll and setting tension can be displayed on the HMI

* Multiple point brake

Single Facer

* Hydraulic rail and guiding system, Hydraulic pressure drive the rail cars move, Hydraulic pressure assist loading and guiding process

* Multiple point brake, Automatic Loading system

* Automatically controlling the rail cars to delivery the mill roll to the center of the machinery (automatic centering)

* Automatically controlling collet aligning with the center of the mill roll and clamp the center tightly

* Automatically unloading the remaining mill roll

Automatic Splicer

* Splicing width: 1650mm

* Maximum diameter of mill roll: 1500mm

* Minimum tensile strength: 3N/mm

* Suitable weight for paper: 95-400g/m2, Splicing speed: 80/220M/min (depending on the quality of paper)

* Tension control range: 10-100kgf

* For electrical part, main control is PLC control, low fault rate and quite stable performance

* The overlap space between new paper and old paper is only 4 centimeters, the contacting place is sticky tightly and the contacting place is not necessary to be picked up which can reduce the loss

* The service life of paper knife cam be up to 15 years without any change

Splicer

Preheater (Rotatable)

* Diameter of pre-heating roller: 1000mm, steel product, 360 degree wrapping angle

* The leading roller is made of aluminum alloy and the diameter is 120mm

* Speed-reducing motor makes the preheater idling with constant speed