Rotator & Breaker for Die cutter

To get more details about our Carton box Smart equipments, pls visit here

Function

High efficient downstream processing system for modern corrugated cardboard production line and printer line.

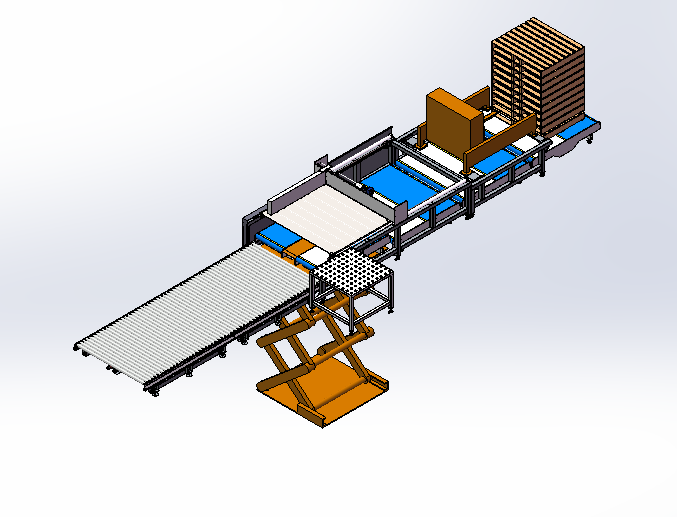

Process instruction

After the stacker of printer die cutter, it needs the logistics system to accomplish the high or middle speed production line. Firstly, after the paper sheets output from the stacker of die cutter, it transports to the Rotator, and rotate +/- 90 degree, then transport to Breaker to Split small piece. Secondly, through the long drive roller, and stack by worker, then discharge & deliver through XY direction Combined Conveyor and connect next station. For the load former line, all pallets were feeded one by one automatically.

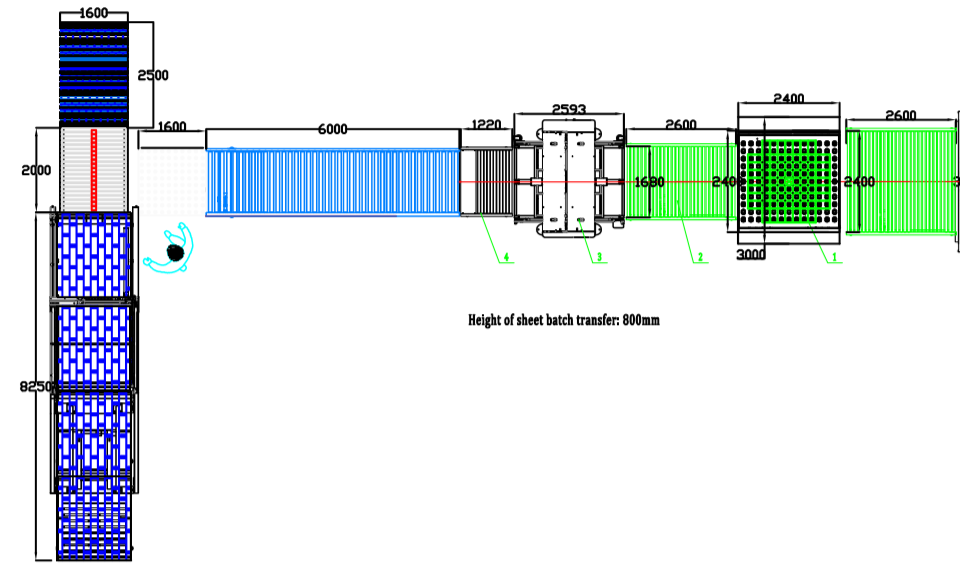

Layout of Auto Breaker & Rotator & Load former line

Main machine & equipment list

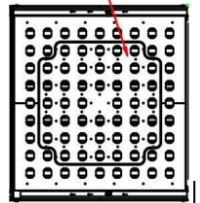

♦ Breaker main body Breaker

• One way blanks breaker

• The machine can do multi-products in one sheet in single direction, like blanks layout as 1x2, 1x3, 1x4, 1x5 and etc. Two breakers work together for blanks layout as 2x2, 2x3, 2x4, 2x,5, 3x3, 3x4, 3x5 and etc.

• It can be used inline with die cutter, folder gluer.

Technical data

| Maximum sheet size | 1650×1200mm |

| Minimum sheet size | 430×360mm |

| Maximum height of batch | 300mm |

| Minimum height of batch | 50mm |

| Maximum speed | 9 times per min |

| Sheet Transfer height | 800 mm |

| Machine size (L x W x H) | 2650×2800×2100 mm |

| Total power consumption | 5kW |

| Power supply | 380V, 3-ph, 50hz |

| Net weight | 4 tons |

♦ Sheet batch rotator

• To complete the rotation of the sheets by 90 degrees, Go straight, Precise positioning rotation, etc.

• Electric control going up & down, and rotation in high precision.

• After the elevation, the motor drives the divider to rotate 90 degrees and then descend. The platform operation uses frequency converter to adjust speed. PLC choose Taiwan FATEK, Frequency converter and Photoelectric both choose Japan Panasonic, Motor choose Taiwan brand, etc.

Technical parameter

| Machine model | DX 2000 |

| Maxi. Sheet size | 2400 x 1600mm |

| Mini. Sheet size | 350*350mm |

| Maxi. Speed | 30m/minute |

| Maxi. loading weight | 30kg |

| Machine dimension | 3000x2400x800mm |

| Net weight | 1200kgs |

| Power | 3kw // 380V-3PH, 50HZ |

Technical parameter

• Lifting platform: hydraulic fixed scissor lifting platform, the rising speed is 3-5m/min, and the falling speed is adjustable.

• Platform: Telescopic Stainless Steel Panel.

• Manual finishing table: in the form of Universal wheel table

• Pallet conveying system: pallet forklift travel and lift adopts chain mechanism, pallet travel is conveyed by modular belt conveyor

• Modular belt sprocket: PP material overall processing

• Conveyor belt: imported POM material module mesh belt, mesh belt thickness: 12mm

• Equipment material: 10t steel plate laser processing

• Mesh belt speed: Max30m/min (frequency conversion speed regulation)

• Electric roller: 63.5*3 bright roller, galvanized surface, transmission mode is chain driven polyurethane friction wheel transmission

• Motor power: conveying motor 1.5KW,Taiwan Wanxin brand

• PLC: Siemens brand

• Inverter: Siemens brand

• Low voltage electrical: Schneider brand

• Sensor: Omron brand

• Appearance: Surface electrostatic spray