Cross Breaker

To get more details about our Carton box Smart equipments, pls visit here

Product Description

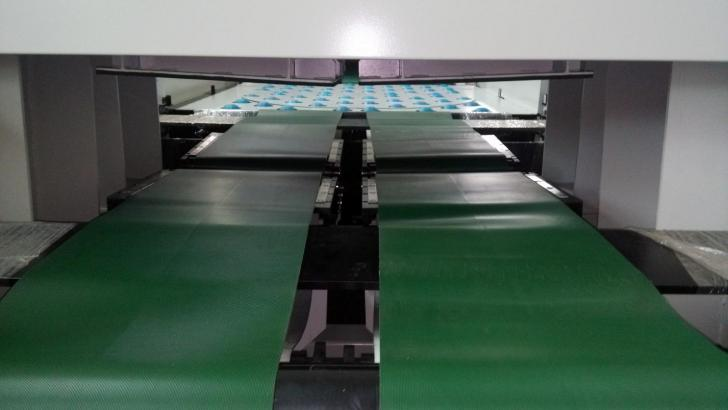

The mainly function of this machine is breaking the connected point for bundle of paper. Sheets will be separated from multiple ups to single up. The breaking action is completed by two parts: top pressure and lower separator. top pressure mechanism can be done around oblique pressure action, and the lower separator will cooperate with the top pressure mechanism to complete the breaking task. The touch screen operating program is more convenient and easy to setting. All the breaking action are completed by hydraulic pressure.

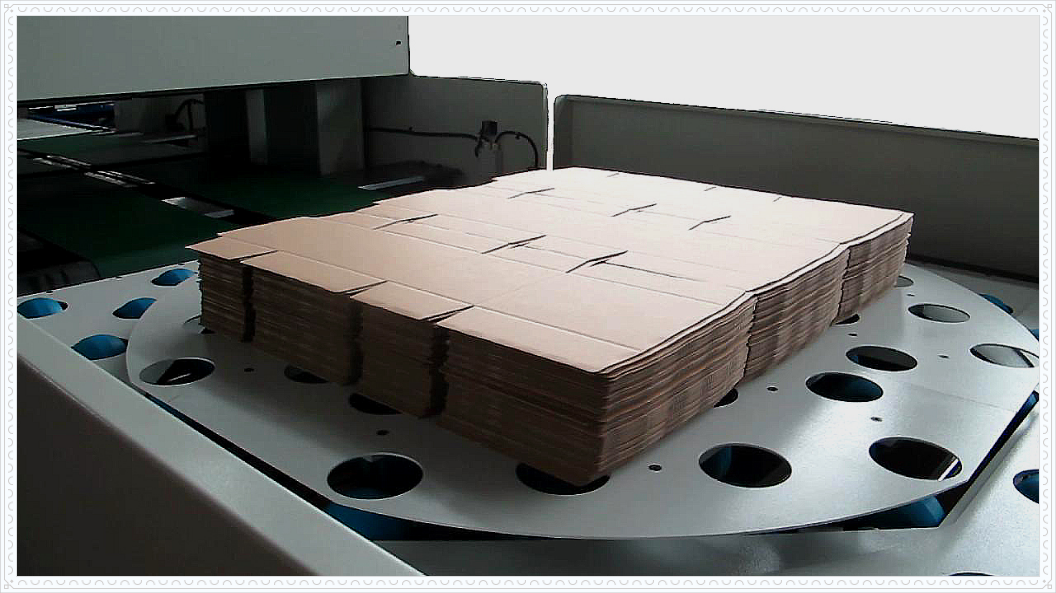

The steering table is a driven conveying device, which is consists of a rotating platform and plastic rolling ball. The product coming from the flatbed die cutter can simply pass through the device traveling on the plastic rolling ball or can be rotated left or right side by 90 degrees.

When the batches stop in the middle of the table, the rotating platform will elevates hydraulically, rotates 90 degree, then dropped back to original position and continue to move on.

According to the request of customer production,The conveyor belt of breaking section can move back and forth, it can guarantee the batches pressured in correct position with the uniform stress. This bundle breaker has a compact structure, it can be suitable to be fitted with flat bed die-cutter.

FEATURES

| ITEM | Description |

| ·Simply operation | All operating controls can be divided into sub-blank setting and quick setup, which are on an external of the machine. |

| ·Save effort | Segregation of sheet batches from E flute to AB flute can be achieved |

| ·High productivity | Adaptable unit used to automatically separate the blanks in bundle format after the die-cutting process. 4 piles can be separated in one process using our high pressure hydraulic system. |

SPECIFICATIONS

| Max. sheet size | 1650 x 1200 mm |

| Min. sheet size | 600 x 500 mm |

| Max. stack height | 270 mm |

| Max. pass width | 1400 mm |

| Actuation time | 2 outs、 4 outs 13 seconds3 outs、 6 outs 25 seconds |

| Data capacity | 1000 |

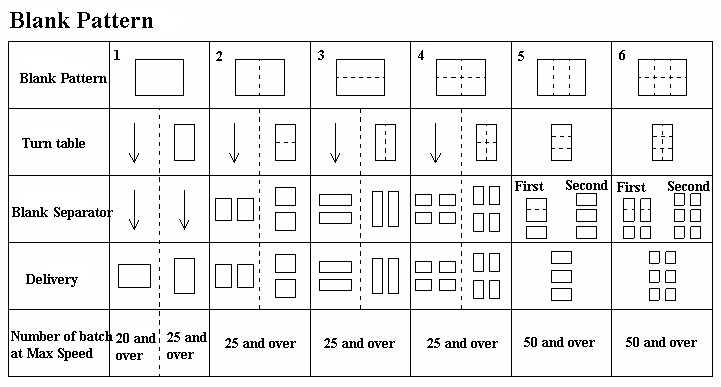

| Breaking pattern | 6 |

| Required power supply | 6KW |

| Exterior sizes(L×W×H) | 4820MM*3013MM*1800MM |

| Weight of machine: | 6560KGS |

When Flat Bed Die Cutting machine running at max. speed (5000i.p.h.):

2 outs and 4 outs: the number of 1 batch should be 25 and over

3 outs and 6 outs: the number of 1 batch should be 50 and over